Good Turnout for Easter Weekend – 68 in attendance and 67 breakfasts were sold. The breakfast line was bigger than expected as several Pecan Plantation family visitors heard about out fantastic pancakes.

Call to Order – Dick Keyt called the meeting to order and summoned all the breakfast crew (Paula Houston, Kris Jaekle, Sid Tucker, Keith Brown, Mike Parrish, and Scott Miller) to the front for special recognition. Dick sought out the guests in attendance. Tanner Boucher, the aspiring Ag Pilot, returned with his dad. His dad is an Airbus pilot for JetBlue. Phil Walter was sporting an impressive B-26 jacket in honor of his dad who flew the Marauder during WWII. Phil is active in the B-26 Marauder Historical Society. Richard T., who worked on Hawk Missile System, has 35 hours of flight time and his considering finally completing his PPL. Curt Farley introduced two young aspiring aviators, Torren and Christian, who he is pressing to become active in the chapter.

Dick received a surprise in the mail from EAA National. Based on the 2022 Annual Report submittal, Chapter 983 received a Gold Recognition Rating! This is a jump of two levels from the prior year Bronze rating. Dick thanked Tom Thibault for researching the criteria and insuring we took credit for everything the chapter was doing. Dick is considering ordering one of the Gold banners to display in the hanger.

The Brazos River 99s will be serving a Pancake Breakfast in conjunction with a Fly In at Granbury Airport on April 22nd. They will begin serving at 0800. An FAA Wings program will be held in the FBO conference room at 0930. Bob Moreau will be speaking about the DFW Airspace.

Initiatives

- Wright Brothers Award – Tom Woodward reported they have 23 submittals and 6 in work. He is still working with the FAA rep on the processing.

- IMC/VMC Club – Tom Woodward has researched what it would take to start the IMC club. He will be attending a training session with EAA National on Wednesday to get a better picture on what is required. Some chapters conduct the club meetings after there Chapter meetings and others do them separate. He said the VMC club would need to be led by a different volunteer.

- Flying Start – This event is a part of the EAA Learn to Fly week May 15-20. It is intended to inspire future aviators by giving them an introductory flight and provide information on the steps to becoming a licensed pilot. Besides the flying part, Tom intends to setup short talks on different aspects of general aviation (powered airplanes, rotorcraft, sailplanes, etc.).

September Fly-In –Greg Walker reported that the Fly In committee continues organizing and holding to the date of September 23rd. He passed around a list of committees and volunteer signup opportunities. Greg emphasized that since the chapter is doing the food prep and food service, we will need a lot of volunteers in that area.

Young Eagles – John Bowen reported the April 10th Young Eagles flight slots are all full and weather is looking good for that day. He mentioned that the chapter receives double credit of $10 per Young Eagle that goes toward EAA Air Academy scholarships. He would like to do at least one more event before the summer heat hits.

John mentioned that Bruce and Geneva McJunkin will be joining him as coordinators to help spread the workload. Their 15 years of experience of coordinating Young Eagles for another EAA chapter in California will help expand the youth outreach. They intend to pursue at least one Ray Aviation Scholarship later this year and potentially youth build of an RC airplane.

Project Reports

Granbury High School S-21 – Don Christiansen reported that the S-21 now has an Airworthiness Certificate from the FAA. He mentioned that two FAA inspectors performed the inspection. Despite several highly experienced eyes on the project, they found several discrepancies that were quickly corrected. Don was impressed with their thoroughness and saved the fee from a DAR. Flying will be accomplished by Don and Mike Robinson. They intend to use the new task-based Phase 1 flight testing.

Glider Project – Dick Keyt reported assembly and rigging of the wings is proceeding in Jordan Normark’s hanger. This is a complicated process achieving the proper dihedral, wing incidence, and sweep.

Featured Speaker – Following a short break, Tim Kurcz presented his extensive knowledge and experience in Threadlocking and Threadsealing Technology. A new Pecan resident, Tim has been a member of the powertrain engineering community for over 50 years, including 26 with Loctite Corporation, and 9 with Jessup Engineering. Tim specialized in engine design and process development for adhesives, sealants, coatings, electro- and electro-less plating, and salt bath nitro-carburizing.

Tim started off by emphasizing the purpose of a threaded fastener is to provide AND maintain clamping force while facilitating assembly and removal. He dispelled a number of myths with a series of True/False questions:

- A properly torqued fastener will never loosen. – FALSE

- It takes thousands of hours of vibration to loosen a fastener. – FALSE

- Split-ring lock washers exert powerful axial force to prevent bolt loosening. – FALSE

- Prevailing torque fasteners prevent the loss of joint integrity. – FALSE

- Nylon rings dampen machinery vibration. – FALSE

- Lock wires and cotter pins are highly effective at preventing fastener loosening. – FALSE

- Threaded fasteners require more torque to loosen than to tighten. – FALSE

- *Safety wire and cotter pins do not stop loosening but do prevent catastrophic loss. – FALSE

Tim explained the proportional relationship between clamping force and tightening torque is driven by an empirically derived constant (K) that indicates lubricity of installation. 85-90% of total tightening torque is caused by thread and head friction. The remaining 10-15% is all that impacts the bolt tension. He further explained how for the same installation torque a high K factor (more friction) results in less than the desired bolt tension which is really what matters. Also, the loosening torque is typically 70-80% of the installation torque. He explained that hard joints, which are flange to flange, loosen through shear/flex/thermal actions between the mating surfaces, whereas soft joints, typically separated by gaskets, are loosened through compression.

Tim then reviewed the three primary means for retaining tightening torque:

- Prevailing-torque devices (Deformed threads, nylon inserts, etc.)

- Free-spinning devices (Serrated heads, toothed washers, etc.)

- Chemical threadlockers (Products such as Loctite using thread “inner space”)

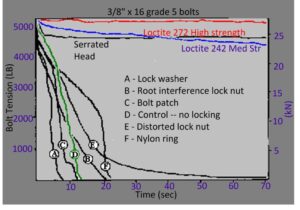

A very compelling comparison is illustrated in this plot showing how chemical threadlockers are superior at maintaining bolt tension (as measured in a specially designed test rig). They also provide an installation lubricity benefit that insures more consistent installation torque. Tim reviewed the Loctite products that provide a range of locking strength and sealing. Finally, Tim had a great story about the best unauthorized T shirt slogan – “Use Loctite or kiss your nuts goodbye”

Tim provided a teaser for an upcoming second presentation on flange sealing using sealing/adhesive products such as Loctite and Permatex. We look forward to hearing all about that at a future meeting and are thankful to have such an incredibly knowledgeable resource in our chapter!

Click below for links to the presentation and technical papers:

Presentation

FIP Gaskets

Fastener Design Part 1

Fastener Design Part 2

Your recap did not include my announcement of the GDJ pancake breakfast hosted by our 99s Saturday April 22nd.

Updated